Abstract

The exponential growth of digital data generation presents an unprecedented challenge and opportunity for modern society. The demand for storage solutions that offer unparalleled durability, density, and energy efficiency, particularly for long-term archival purposes, has intensified. Ceramic-based data storage technologies have emerged as a highly promising, disruptive avenue to address these multifaceted challenges. This comprehensive report provides an in-depth, scholarly examination of ceramic data storage, focusing intently on the innovative methodologies and systems introduced by Cerabyte, a pioneering entity in this burgeoning field. We delve into the foundational material science and advanced physics that underpin ceramic storage approaches, offering a detailed analysis of the intricate interactions between ultrashort laser pulses and ceramic nanolayers. A thorough comparative analysis is conducted against other prominent emerging ultra-long-term archival technologies, such as DNA data storage and glass-based volumetric storage, highlighting the unique advantages and trade-offs inherent in each. Furthermore, the report explores the sophisticated intricacies of laser writing and reading mechanisms, elaborating on the precision engineering required for nanoscale data inscription and retrieval. Significant attention is paid to the formidable manufacturing scalability challenges that must be overcome for widespread adoption, proposing potential solutions and strategic pathways. Finally, we consider the expansive potential applications of ceramic data storage, extending far beyond traditional enterprise archival uses to critical domains such as scientific research, deep space exploration, cultural heritage preservation, and national security, thereby positioning this technology as a cornerstone for the future of information preservation in the ‘yottabyte era’.

Many thanks to our sponsor Esdebe who helped us prepare this research report.

1. Introduction

The digital age has unequivocally ushered in an era of unprecedented data proliferation, transforming virtually every facet of human endeavor. Projections indicate a staggering escalation, with the global data sphere estimated to reach 175 zettabytes (ZB) by 2025, and potentially exceeding a yottabyte (YB) in the subsequent decades [2, 10]. This overwhelming deluge of information—ranging from critical scientific discoveries and vast corporate archives to personal digital legacies and governmental records—mandates storage solutions that not only accommodate immense volumes but also guarantee their immutable preservation over exceptionally extended periods. Traditional archival media, including magnetic tapes (e.g., LTO) and hard disk drives (HDDs), are increasingly demonstrating inherent limitations concerning long-term durability, raw capacity, energy consumption, and environmental footprint. Magnetic tapes typically possess lifespans of 30-50 years under optimal conditions, requiring periodic ‘refreshing’ and data migration, a process that is both costly and energy-intensive. Hard drives, while offering faster access, are prone to mechanical failure and have even shorter practical archival lifespans, often necessitating replacement every 3-5 years. Optical disks (e.g., Blu-ray archival discs) provide somewhat better longevity but struggle with density requirements for exabyte-scale archives.

In direct response to these burgeoning demands and the inherent shortcomings of conventional storage paradigms, innovative technologies have been rigorously developed and explored. Among these, ceramic-based data storage has emerged as a particularly compelling and transformative contender. This technology capitalizes on the intrinsic stability, resilience, and inertness of advanced ceramic materials to forge a new class of storage media. Such media are engineered to endure extreme environmental conditions, ranging from elevated temperatures and radiation exposure to chemical degradation, while simultaneously offering significantly enhanced data density and longevity.

Cerabyte, a pioneering German startup established in 2022, has rapidly positioned itself at the vanguard of this innovation wave. The company is actively developing a novel storage system that fundamentally redefines long-term data preservation. Their approach leverages ultra-thin ceramic nanolayers, typically only tens of nanometers thick (approximately 50 to 100 atoms), precisely deposited onto robust, ultra-thin glass substrates [1, 2]. This sophisticated architecture enables data to be inscribed with unparalleled precision and durability. Cerabyte’s vision extends beyond mere archival, aiming to provide a high-performance, energy-efficient, and cost-effective solution for what they term the ‘yottabyte era,’ a future where data volumes dwarf current estimations and demand radically different storage infrastructures [10]. The company’s strategic collaborations, including investments from entities like Western Digital and In-Q-Tel (a CIA-backed venture capital firm), underscore the perceived strategic importance and disruptive potential of their technology [4, 11, 12].

Many thanks to our sponsor Esdebe who helped us prepare this research report.

2. Material Science and Physics of Ceramic Storage Approaches

The fundamental viability of ceramic-based data storage is rooted deeply in the extraordinary properties of ceramic materials. These materials are broadly defined as inorganic, non-metallic solids, typically comprising metallic and non-metallic elements bonded primarily through ionic or covalent bonds. Their crystalline or sometimes amorphous structures impart a suite of advantageous characteristics: exceptional hardness, high melting points, remarkable chemical inertness, and inherent resistance to thermal degradation, corrosion, and wear [13]. These attributes make ceramics uniquely suitable for data storage applications demanding extreme longevity and stability in diverse and often harsh environments.

2.1. The Role of Ceramic Materials and Nanolayers

The core principle underpinning Cerabyte’s ceramic data storage involves encoding digital information into the physical structure of a precisely engineered ceramic material. The choice of ceramic is critical, favoring materials that exhibit high thermal stability, chemical inertness, and an amenable response to focused laser energy. While specific proprietary compositions are typically guarded, general candidates for such applications often include oxides (e.g., aluminum oxide, silicon dioxide, titanium dioxide), nitrides (e.g., silicon nitride), or even amorphous carbon-based layers. These materials are selected for their ability to form stable, uniform thin films and their resistance to physical and chemical alteration post-inscription.

Cerabyte’s innovative approach centers on the deposition of a ceramic nanolayer, ranging from approximately 50 to 100 atoms (or 5-10 nanometers) in thickness, onto a pristine, ultra-thin glass substrate [1]. The rationale behind employing such extremely thin nanolayers is multi-fold. Firstly, their nanoscale dimension allows for extremely high data density, as the physical features inscribed can be commensurately small. Secondly, thin film deposition techniques (e.g., atomic layer deposition (ALD), physical vapor deposition (PVD), chemical vapor deposition (CVD), or sputtering) offer exquisite control over material composition, thickness uniformity, and crystalline structure, all of which are paramount for consistent data encoding and reliable retrieval. Thirdly, the optical properties of thin films can be precisely engineered to optimize laser interaction and subsequent optical detection. Finally, minimizing the amount of active material reduces costs and potentially enhances writing speed due to less material needing modification.

2.2. The Glass Substrate: A Foundation for Durability

Equally crucial to the system’s performance is the choice of the substrate: ultra-thin glass. Glass, particularly high-purity fused silica or specialized borosilicate glasses, offers a complementary set of desirable properties. It is optically transparent, chemically inert, possesses excellent thermal stability, and is largely immune to electromagnetic interference. Furthermore, the glass manufacturing industry is mature and highly scalable, providing a robust and cost-effective foundation for producing the media. The combination of a highly durable ceramic nanolayer on a stable glass substrate creates a composite medium that combines the best attributes of both: the data-encoding resilience of ceramics with the optical transparency, mechanical strength, and manufacturing scalability of glass. Careful engineering is required to ensure strong adhesion between the ceramic layer and the glass substrate and to manage any potential thermal expansion mismatches during manufacturing and operation.

2.3. Data Encoding and Preservation Mechanisms

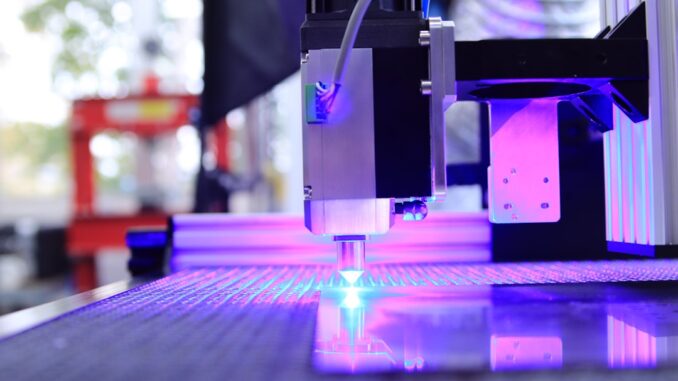

Data is inscribed onto the ceramic nanolayer by precisely etching microscopic, nanoscale holes or pits using femtosecond lasers [1, 13]. These pits, or regions of modified material, create patterns that correspond to binary digital information. The physical change imparted by the laser is a permanent alteration of the ceramic’s structure or topography, resulting in localized changes in optical properties (e.g., reflectivity, refractive index, light scattering). These changes are incredibly stable because they are etched into the atomic or molecular structure of an inert ceramic material.

The extraordinary stability of ceramic materials ensures the integrity of the inscribed data over geological timescales. Unlike magnetic or optical data, which can degrade due to magnetic field decay, dye fading, or material oxidation, ceramic-based data relies on direct physical alterations within a chemically stable matrix. Cerabyte claims a potential lifespan exceeding 5,000 years for their storage media, a testament to the inherent resilience of the ceramic-glass composite [5]. This longevity is crucial for true archival storage, eliminating the need for periodic data migrations that plague conventional technologies and significantly reducing the total cost of ownership (TCO) over the long term.

2.4. Physics of Femtosecond Laser-Material Interaction

The ability to create nanoscale features with precision is central to achieving high data density. This is accomplished through the sophisticated interaction of ultrashort laser pulses, specifically femtosecond lasers, with the ceramic material. Femtosecond lasers emit pulses with durations typically ranging from a few femtoseconds (10^-15 seconds) to hundreds of femtoseconds. The key physical advantage of such ultrashort pulses lies in their exceptionally high peak power, even with relatively low average power. This high peak power enables non-linear optical effects to dominate the laser-material interaction, rather than conventional thermal absorption.

When a femtosecond laser pulse interacts with the ceramic nanolayer, the material absorbs photons in a multi-photon absorption process, where electrons are excited to higher energy states by absorbing multiple photons simultaneously. This leads to extremely rapid ionization and the formation of a high-density plasma. Because the pulse duration is shorter than the typical electron-phonon coupling time (the time it takes for electrons to transfer energy to the crystal lattice as heat), the energy is deposited into the electronic system before significant thermal diffusion can occur. This ‘cold ablation’ or ‘non-thermal ablation’ mechanism results in highly localized material modification or removal, creating nanoscale features with minimal collateral thermal damage to the surrounding material [1, 13].

This precise, non-thermal interaction allows for the creation of features far smaller than the diffraction limit of light, which would otherwise dictate the minimum feature size achievable with conventional lasers. By precisely controlling parameters such as pulse energy, repetition rate, focusing optics (numerical aperture), and scanning speed, highly defined nanostructures can be consistently inscribed. This unparalleled control over the material modification process is what enables the high-density storage of information, reportedly allowing Cerabyte’s system to write up to 2 million bits with a single laser pulse, likely through a combination of highly efficient patterning within a small focal volume or advanced spatial light modulation techniques for parallel inscription [4].

Many thanks to our sponsor Esdebe who helped us prepare this research report.

3. Comparison with Other Emerging Ultra-Long-Term Archival Technologies

The quest for ultra-long-term data storage has spurred the development of several innovative technologies, each presenting unique advantages and confronting distinct challenges. Understanding their comparative merits and drawbacks against ceramic storage, particularly Cerabyte’s approach, is essential for a holistic perspective.

3.1. DNA Data Storage

DNA data storage represents the pinnacle of theoretical data density. It involves encoding digital information (binary 0s and 1s) into the nucleotide sequences (A, T, C, G) of synthetic DNA molecules. The concept leverages the natural information-carrying capacity of DNA, which has evolved over billions of years to store genetic blueprints. Researchers have successfully encoded vast amounts of data, including entire books, videos, and operating systems, into synthetic DNA strands.

Mechanism: Digital data is first converted into a sequence of A, T, C, G bases. These sequences are then chemically synthesized into actual DNA molecules. For retrieval, the DNA is sequenced, and the base pairs are translated back into digital information. Techniques like polymerase chain reaction (PCR) can be used to amplify DNA copies, facilitating retrieval and replication.

Advantages:

* Extraordinary Density: Theoretically, a single gram of DNA can store an astounding 215 petabytes (PB) of data, making it orders of magnitude denser than any other known storage medium. This is its most compelling advantage, potentially solving the physical space crunch in data centers.

* Natural Longevity: Under optimal, protected conditions (e.g., lyophilized and kept cold and dark), DNA can remain stable for thousands, if not millions, of years, as evidenced by ancient DNA recovered from fossils.

* Future-Proof: DNA is the universal language of life; as long as humanity exists and understands biology, DNA will be readable, bypassing technological obsolescence issues.

Disadvantages:

* High Cost and Complexity: The current processes for DNA synthesis and sequencing are prohibitively expensive and time-consuming for large-scale data storage. Error rates during synthesis and sequencing also add complexity and cost for error correction.

* Slow Read/Write Speeds: Writing data involves chemical synthesis, which is a slow, sequential process. Reading involves sequencing, also a relatively slow operation, making it suitable only for ‘cold’ archives with infrequent access.

* Stability Challenges (Operational): While DNA is naturally stable, protecting it from degradation (e.g., moisture, heat, UV light) in an active archival system requires stringent environmental controls. Chemical degradation in aqueous solutions can occur over time.

* Random Access Limitations: Retrieving a specific piece of data from a large pool of DNA molecules is akin to finding a specific needle in a vast haystack, requiring sophisticated indexing and molecular sorting techniques.

Key Players: Microsoft (Project H2), Twist Bioscience, Illumina, Catalog Technologies.

3.2. Glass-Based Volumetric Storage (e.g., Microsoft Project Silica)

Glass-based volumetric storage, exemplified by Microsoft’s Project Silica, offers another compelling vision for ultra-long-term archiving. This technology encodes data within the bulk volume of highly durable glass, typically fused quartz, using sophisticated laser writing techniques.

Mechanism: Femtosecond lasers are used to create three-dimensional nanoscale gratings, voids, or refractive index changes directly within the interior of a quartz glass substrate. These modifications are permanent, physically altering the atomic structure of the glass. Data can be written in multiple layers within the glass, offering volumetric storage. Reading involves illuminating these internal structures with polarized light and using machine learning algorithms to decode the patterns through changes in light refraction and polarization.

Advantages:

* Extreme Durability: Quartz glass is incredibly robust, resistant to heat (up to 1,000°C), water, electromagnetic pulses (EMP), and many chemicals. This makes the data virtually indestructible under most environmental conditions.

* Exceptional Longevity: Claimed lifespans extend to millions of years, far surpassing any other storage medium.

* Volumetric Density: Storing data in three dimensions allows for very high theoretical densities, although practical implementations are still being optimized.

* Passive Archive: Once written, the data requires no power to maintain and is largely immune to external influences.

Disadvantages:

* High Energy Consumption for Writing: The process of permanently altering bulk glass with femtosecond lasers is energy-intensive, making the write operation costly and slow.

* Specialized Equipment: Both writing and reading require highly specialized, precision laser systems and advanced optical detection, which are complex and expensive.

* Scalability Challenges: Manufacturing large quantities of high-purity quartz media and scaling the complex write/read systems to meet data center demands is a significant hurdle.

* Slower Access Speeds: While reading is faster than DNA storage, it is still considerably slower than traditional archival (e.g., tape) or active storage, positioning it firmly in the ‘cold’ archive category.

Key Players: Microsoft (Project Silica), University of Southampton (5D Data Storage).

3.3. Holographic Data Storage

Holographic data storage utilizes light interference patterns to record information throughout the volume of a photosensitive material, typically a photorefractive crystal or photopolymer.

Mechanism: A reference laser beam and an object laser beam (modulated with data) interfere within the recording medium, creating a complex 3D interference pattern that permanently alters the material’s properties (e.g., refractive index). This pattern, a hologram, stores an entire ‘page’ of data (thousands to millions of bits) simultaneously. Reading involves illuminating the hologram with the reference beam, recreating the object beam, which is then detected by a camera.

Advantages:

* High Density: Volumetric storage potentially offers very high data densities.

* Fast Transfer Rates: An entire page of data can be written or read in parallel, theoretically offering extremely high transfer rates.

* Random Access Potential: Individual pages can be accessed quickly by adjusting the angle or wavelength of the reference beam.

Disadvantages:

* Material Limitations: Photosensitive materials can suffer from issues like fatigue, scatter, dark decay, and thermal instability, which affect long-term archival reliability and data integrity.

* Complex Optics: Requires highly precise and stable optical systems, making devices complex and expensive.

* Vulnerability: Susceptible to material defects, environmental factors, and precise alignment issues.

* Limited Commercial Success: Despite decades of research, widespread commercial adoption has been elusive due to the practical challenges of material stability and system complexity.

Key Players: InPhase Technologies (defunct), but research continues in academia and specialized labs.

3.4. Comparison with Ceramic Storage (Cerabyte)

Cerabyte’s ceramic-based storage system offers a compelling alternative by strategically combining the best attributes of several approaches while mitigating their respective drawbacks:

- Durability and Longevity: Similar to glass-based volumetric storage, ceramic nanolayers on glass offer extreme resistance to environmental factors (heat, water, chemicals, EMP) and promise lifespans in millennia (5,000+ years), significantly outperforming magnetic tapes and optical media, and competitive with the ‘passive’ stability of DNA and bulk glass.

- Data Density: While not matching the theoretical density of DNA, ceramic storage aims for very high practical densities (e.g., 100 PB per rack by 2030, with future targets of 100,000 PB per rack), which is orders of magnitude greater than traditional media [5, 7, 8, 9]. This is achieved through nanoscale patterning on surfaces, potentially offering a more immediately scalable path than volumetric encoding for initial commercial deployment.

- Scalability and Manufacturing: A key advantage Cerabyte emphasizes is leveraging existing, high-volume glass manufacturing processes [3]. This significantly reduces the time and cost associated with media production compared to bespoke quartz blocks for Project Silica or the complex synthesis of DNA. The surface-based encoding may also simplify the write/read head design compared to complex volumetric systems.

- Access Speed and Latency: Cerabyte’s system is designed for relatively fast data access, positioning itself as an ‘active archive’ or ‘deep archive’ solution rather than purely ‘cold’ storage. Optical reading allows for rapid, potentially parallel retrieval of data, offering better latency than DNA or bulk glass storage, which can take minutes to hours to retrieve specific files.

- Energy Efficiency and TCO: By eliminating the need for constant power to maintain data (unlike HDDs) and reducing frequent data migrations (unlike tape), ceramic storage promises significantly lower energy consumption and a dramatically reduced TCO over its lifespan. This is a critical factor for hyperscale data centers facing massive energy bills.

- Operational Simplicity: The system aims for integration into existing data center architectures, potentially using robotic library systems similar to those for tape, but with media that is far more robust and requires less environmental control than DNA or active optical media.

In essence, Cerabyte seeks a sweet spot: offering durability comparable to the most resilient emerging technologies, density vastly superior to current archival, and a manufacturing/operational model that is more scalable and cost-effective for large-scale enterprise and hyperscale deployment. It bridges the gap between ultra-cold, extremely slow archival (DNA, bulk glass) and relatively short-lived, higher-performance traditional archival (tape).

Many thanks to our sponsor Esdebe who helped us prepare this research report.

4. Laser Writing and Reading Mechanisms

The sophisticated processes of data inscription and retrieval in ceramic-based storage systems are orchestrated by advanced laser technologies, demanding extreme precision and speed. These mechanisms are the operational core of Cerabyte’s solution, translating digital bits into physical patterns and back again.

4.1. Advanced Writing Mechanism: Precision and Throughput

Data is permanently written onto the ceramic nanolayer using highly focused femtosecond laser pulses. The mechanism involves more than simple ‘etching’; it is a precisely controlled material modification process.

Laser Parameters and Interaction Dynamics:

* Wavelength Selection: The laser’s wavelength is carefully chosen to optimize energy absorption by the ceramic material, typically in the visible or near-infrared spectrum, where multiphoton absorption is efficient.

* Pulse Energy and Repetition Rate: The energy per pulse (nanojoules to microjoules) is critical for inducing localized non-thermal ablation or phase changes without affecting surrounding material. High repetition rates (MHz range) are employed to achieve high writing throughput.

* Beam Focusing: High numerical aperture (NA) objective lenses are used to focus the laser beam to a diffraction-limited spot size, typically in the sub-micrometer range, enabling the creation of nanoscale features. Advanced beam shaping techniques can further enhance resolution.

* Spatial Light Modulation (SLM): While direct scanning is possible, the claim of ‘2 million bits with a single laser pulse’ strongly suggests the use of advanced parallel writing techniques, possibly involving SLMs. An SLM can dynamically shape the laser wavefront, allowing for the simultaneous creation of complex two-dimensional patterns or even three-dimensional volumetric structures (e.g., multiple pits in a small area or an interference pattern) within the single pulse’s focal volume. This massively boosts writing speed by parallelizing the bit inscription process.

* Material Response: The interaction within the ceramic nanolayer involves femtosecond-scale processes: rapid electron excitation, plasma formation, and subsequent material ejection or structural rearrangement. The critical aspect is the minimal heat-affected zone (HAZ), which ensures that adjacent data bits are not compromised during writing. This ‘cold’ process prevents thermal stress, melting, or recrystallization that could degrade the stability or integrity of the inscribed information.

Error Correction and Verification: To ensure data integrity, especially during high-speed writing, sophisticated error correction codes (ECC) are employed. These codes add redundancy to the data, allowing for the detection and correction of errors caused by material imperfections, laser fluctuations, or minor manufacturing variances. A ‘read-after-write’ verification step can be integrated into the system, where a small portion of the newly written data is immediately read back and compared, ensuring successful inscription before the media is archived. Advanced calibration routines are also essential to maintain consistent laser performance and focusing accuracy across the entire media surface.

Throughput Optimization: Achieving high writing speeds is paramount for commercial viability. This involves: multi-beam writing (using multiple lasers or splitting a single beam into several parallel beams, each writing simultaneously), rapid galvanometer mirrors for precise and fast beam steering, and high-speed mechanical stages for moving the media. The goal is to maximize the area of data written per unit time, balancing resolution with throughput.

4.2. Sophisticated Reading Mechanism: Rapid and Reliable Retrieval

Data retrieval from the ceramic nanolayer is achieved through advanced optical detection techniques. The nanoscale features created during the writing process alter the optical properties of the ceramic material, making the encoded information optically readable.

Illumination and Detection:

* Laser Illumination: A non-destructive, lower-power laser beam (often at a different wavelength or power level than the writing laser) is used to illuminate the inscribed ceramic layer. The interaction of this light with the nanofeatures produces distinct optical signals.

* Optical Microscopy and High-Resolution Cameras: High-resolution optical microscopes equipped with sensitive CCD or CMOS cameras are used to capture the light patterns. These patterns can manifest as variations in transmitted light intensity, reflected light intensity, phase shift, or polarization changes. For instance, etched pits might scatter light differently than unetched areas, or create phase shifts that can be detected using phase-contrast microscopy.

* Signal Processing and Decoding Algorithms: The captured optical images are then subjected to sophisticated signal processing. This involves image analysis algorithms that can detect, identify, and decode the nanoscale patterns with high accuracy. Machine learning techniques, particularly deep learning for image recognition, are increasingly being applied to improve the robustness and speed of decoding, especially in the presence of noise or subtle material variations.

Parallel Reading and Data Retrieval: One of the key advantages of optical reading is the potential for parallel data access. A single image captured by the camera can encompass a vast array of etched bits. By using a large field of view and processing multiple image sections simultaneously, data can be retrieved much faster than bit-by-bit serial reading. Cerabyte’s system is designed for rapid data access, implying the ability to scan large areas of the media quickly and efficiently. Robotic handlers would select and present the appropriate media cartridge to the read station, where optical scanners would quickly acquire data.

Data Integrity in Reading: Error detection codes (EDC) are crucial during reading to identify and potentially correct any bit errors that might occur during retrieval due to dust, minor scratches, or reading system imperfections. The optical system must be robust against environmental factors like dust particles on the media surface, potentially employing advanced filtration or self-cleaning mechanisms. The design also accounts for the long-term stability of the optical contrast, ensuring that the written features remain distinct and readable over centuries.

4.3. The Cerabyte System Architecture: From Media to Rack

Beyond the media and the laser mechanics, Cerabyte envisions an integrated system designed for hyperscale data centers. This architecture would likely comprise:

* Media Cartridges: Robust, standard-sized cartridges housing multiple ceramic-glass media platters.

* Robotic Libraries: Automated systems similar to existing tape libraries, capable of retrieving, loading, and unloading cartridges from racks to read/write units.

* Read/Write Units: Dedicated modules containing the precision femtosecond lasers, focusing optics, and high-resolution cameras for data inscription and retrieval.

* Controller Software: A sophisticated software layer managing data placement, retrieval requests, error handling, and interfacing with existing data center storage management systems (e.g., object storage APIs).

* Data Center Integration: Designed to fit into standard server racks (e.g., 42U racks), allowing for seamless integration into existing infrastructure and offering a compelling density per rack unit [9].

This holistic system design aims to provide not just a durable medium, but a practical, high-performance, and energy-efficient solution for massive, long-term data archives, thereby facilitating the transition towards the ‘yottabyte era’ of data storage [3, 10].

Many thanks to our sponsor Esdebe who helped us prepare this research report.

5. Manufacturing Scalability Challenges

While ceramic-based data storage, particularly Cerabyte’s innovative approach, offers compelling advantages for ultra-long-term data preservation, transitioning from laboratory proof-of-concept to large-scale commercial manufacturing presents several formidable challenges. Addressing these will be crucial for widespread adoption and economic viability.

5.1. Material Consistency and Quality Control

Achieving and maintaining uniformity in the ceramic nanolayer’s thickness, composition, and physical properties is paramount. Any variations can directly translate into inconsistencies in laser-material interaction, leading to errors during data encoding, reduced data density, or compromised data integrity during retrieval. Similarly, the glass substrate must be of extremely high quality, free from microscopic defects that could interfere with the nanolayer or the laser process.

Challenges:

* Nanolayer Deposition: Techniques like ALD, PVD, or sputtering, while precise, can be slow for very large areas or suffer from uniformity issues over large substrates. Controlling the stoichiometry and crystallinity of the ceramic film at the nanoscale across millions of individual substrates is a significant challenge.

* Substrate Quality: Glass production, even for high-grade applications, can introduce surface roughness, particulate contamination, or internal stresses. These defects, while acceptable for many uses, become critical at the nanoscale where data is inscribed.

* Defect Management: Even with stringent controls, microscopic defects will inevitably occur. Developing strategies to either prevent them, work around them (e.g., through error correction or re-routing data), or effectively screen them out without compromising throughput is essential.

Potential Solutions:

* Advanced Deposition Technologies: Investing in cutting-edge deposition systems with real-time feedback and control loops to ensure precise and uniform nanolayer growth over large areas.

* In-line Metrology: Implementing sophisticated in-line metrology tools (e.g., ellipsometry for thickness, atomic force microscopy (AFM) for surface roughness, optical profilometry for topography) at every stage of production to monitor quality and provide immediate feedback for process adjustment.

* Automated Optical Inspection (AOI): High-speed AOI systems can rapidly scan media for macroscopic and microscopic defects, allowing for early rejection of flawed substrates or nanolayers.

* Redundancy and Error Correction: Designing the data encoding scheme with robust error correction codes (ECC) can tolerate a certain level of media imperfections without data loss.

5.2. Process Integration and Throughput

Integrating the complex femtosecond laser writing process into existing, high-volume glass manufacturing workflows requires meticulous engineering. The speed of data inscription must be compatible with the desired media production rates, and the entire process must be efficient and cost-effective.

Challenges:

* Speed Disparity: Femtosecond laser writing, even with parallelization, can be slower than the continuous-flow nature of glass manufacturing. Bottlenecks at the writing stage would severely limit overall production capacity.

* Precision Alignment: Maintaining nanometer-level precision for laser focusing and material positioning across large, moving substrates in a high-throughput environment is technically demanding.

* Environmental Control: The laser writing process typically requires stringent cleanroom conditions to prevent dust or contaminants from interfering with the highly focused laser or settling on the media surface, adding to the operational complexity and cost.

* Equipment Downtime: Specialized laser systems are complex and can be prone to downtime if not designed for industrial robustness and reliability. Maintenance and calibration procedures must be streamlined.

Potential Solutions:

* Multi-beam and Multi-head Systems: Employing arrays of lasers or multiple writing heads operating in parallel can drastically increase writing throughput, effectively matching the speed of substrate preparation.

* Advanced Robotics and Automation: High-precision robotic handling systems can ensure accurate positioning and seamless transfer of media between process steps, minimizing human intervention and potential for error.

* Integrated Cleanroom Environments: Designing dedicated, localized clean zones for the laser writing stage within the larger manufacturing facility can manage environmental control efficiently without requiring the entire plant to be a cleanroom.

* Modular and Redundant Systems: Designing writing units as modular, easily replaceable components can minimize downtime, as a malfunctioning module can be swapped out quickly while others continue operation. Redundancy ensures continuous production.

5.3. Cost Considerations and Total Cost of Ownership (TCO)

The high initial capital expenditure (CAPEX) for specialized equipment, particularly femtosecond lasers and advanced deposition systems, can be a significant barrier to entry. This must be offset by compelling TCO benefits over the long term.

Challenges:

* CAPEX: Femtosecond lasers are expensive. The cost of precision optics, motion stages, and advanced metrology equipment adds substantially to the initial investment.

* OPEX: Energy consumption, even for ‘cold’ ablation, can be considerable for high-power lasers and associated cooling systems. Maintenance, specialized consumables, and highly skilled personnel contribute to operational costs.

* Economic Viability: The unit cost of the media must be competitive, especially when compared to established archival solutions like tape, which are already very low-cost per TB for cold storage, albeit with shorter lifespans and higher refresh costs.

Potential Solutions:

* Cost-Effective Laser Development: Driving down the manufacturing cost of industrial-grade femtosecond lasers through design optimization, mass production, and competition among suppliers.

* Energy Efficiency Optimization: Developing more energy-efficient laser sources and optimizing the writing process to minimize pulse energy and repetition rates required for reliable inscription.

* Leveraging Existing Infrastructure: As Cerabyte aims, utilizing existing glass manufacturing lines as much as possible reduces the need for entirely new greenfield facilities, thereby lowering CAPEX.

* Demonstrating TCO Benefits: Clearly articulating and quantifying the long-term TCO advantages (e.g., eliminating data migrations, reduced energy for data maintenance, increased durability, smaller physical footprint) to potential customers. The extended lifespan directly translates to fewer replacements and significantly lower administrative overhead over decades.

* Phased Rollout and Strategic Partnerships: Starting with niche, high-value archival markets and gradually scaling up, while forging partnerships with key industry players (like Western Digital) and hyperscalers, can de-risk investment and accelerate adoption.

5.4. Supply Chain and Sustainability

Challenges:

* Raw Material Sourcing: Ensuring a stable and ethical supply chain for specialized ceramic precursors and high-purity glass, some of which may involve rare or strategically important materials.

* Environmental Impact: The energy consumption and potential waste generation during high-volume manufacturing need to be carefully managed to ensure the technology is environmentally sustainable.

Potential Solutions:

* Diversified Sourcing and Material Innovation: Exploring alternative ceramic compositions or glass types to reduce reliance on specific, potentially constrained raw materials. Developing environmentally friendly synthesis routes.

* Green Manufacturing Practices: Implementing energy-efficient manufacturing processes, reducing waste, and designing media for recyclability at end-of-life. The inherent longevity of the media itself is a significant sustainability advantage, as it minimizes material consumption for data refreshes.

Overcoming these scalability challenges will require continued innovation, significant investment, and close collaboration between material scientists, laser engineers, manufacturing experts, and data center operators. However, the potential rewards – a truly durable, high-density, and energy-efficient archival solution – are substantial enough to warrant the effort.

Many thanks to our sponsor Esdebe who helped us prepare this research report.

6. Potential Applications Beyond Enterprise Archival

While traditional enterprise archival is a primary driver for ceramic-based data storage, its unparalleled durability, density, and resilience open doors to a myriad of specialized and critical applications across diverse sectors. These applications extend far beyond simply storing corporate records, addressing fundamental needs for long-term data preservation in the face of environmental extremes, scientific longevity, and the safeguarding of human civilization’s digital legacy.

6.1. Deep Archival and Cold Data Storage for Hyperscale Data Centers

Ceramic storage is exquisitely suited for the burgeoning ‘cold data’ market, particularly within hyperscale cloud environments. Cold data refers to information that is accessed infrequently, perhaps once a month or less, but must be retained for extended periods for regulatory, compliance, or historical reasons. This category includes historical financial transactions, regulatory compliance logs, long-term backups, legal discovery documents, and massive datasets used for periodic analytics or machine learning model training.

Impact:

* Massive Cost Reduction: By eliminating the need for powered storage (like HDDs) or frequent data migrations (like tape), ceramic storage drastically reduces energy consumption and operational overhead, leading to substantial TCO savings for cloud providers and large enterprises.

* Enhanced Compliance and Immutability: The physical immutability of the inscribed data ensures compliance with stringent data retention regulations (e.g., GDPR, HIPAA, SOX) and provides an unalterable audit trail.

* Reduced Footprint: The high data density means fewer physical racks and data center space are required, contributing to further cost and environmental benefits.

* Faster ‘Cold’ Access: Compared to current ultra-cold storage options like object storage tiers that can take hours to retrieve data from deep archives, ceramic storage aims for relatively faster access, bridging the gap to ‘warm’ archive performance.

6.2. Scientific Research and Data Preservation

The scientific community generates petabytes, and soon exabytes, of irreplaceable data from experiments, simulations, and observations. This includes climate records, genomic sequences, astronomical survey data, particle physics experiment results, and high-resolution imaging from medical research. The long-term preservation of this data is critical for reproducibility, future analysis, and intergenerational scientific progress.

Impact:

* Long-term Integrity: Ensures that valuable research data remains intact and accessible for centuries, allowing future scientists to validate past findings or discover new insights as analytical techniques evolve.

* Data Verifiability: Provides an immutable record, essential for the integrity and trustworthiness of scientific findings, especially in fields like climate science or public health where data can be politically sensitive.

* Global Collaborations: Facilitates the secure sharing and archiving of vast international datasets, ensuring continuity for multi-decade projects (e.g., Square Kilometre Array, Large Hadron Collider).

* Computational Genomics: Storing entire population genomic datasets securely for personalized medicine and evolutionary studies.

6.3. Space Exploration and Planetary Science

Space missions, particularly long-duration probes to distant planets or deep space, present some of the most challenging environments for data storage. Ceramic storage is uniquely positioned to meet these demands.

Impact:

* Radiation Hardness: Ceramic materials are inherently more resistant to cosmic radiation and solar flares than semiconductor-based memory or magnetic media, which can suffer from single-event upsets (SEUs) or long-term degradation.

* Extreme Temperature Tolerance: Data can withstand the extreme temperature fluctuations of space environments (e.g., deep space cold, planetary surface heat) without degradation.

* Vacuum Stability: Unlike some organic-based media or magnetic films, ceramics are stable in a vacuum, preventing outgassing or material changes.

* Long-Duration Missions: Ideal for recording mission telemetry, scientific findings (e.g., planetary surface images, atmospheric data, geological surveys), and crew logs for missions spanning decades or centuries, ensuring data survival until it can be transmitted or retrieved.

* ‘Time Capsules’ for Future Generations/Civilizations: Could serve as an incredibly durable medium for storing fundamental human knowledge or messages for future generations, either on Earth or for extraterrestrial encounters (akin to the Voyager Golden Records, but with vastly more capacity).

6.4. Cultural Heritage and Digital Legacy Preservation

The world’s cultural heritage is increasingly being digitized, from ancient manuscripts and artworks to historical photographs and oral histories. Preserving these digital assets for millennia is essential to prevent a ‘digital dark age’ where vast amounts of human history and creativity could be lost due to media obsolescence and degradation.

Impact:

* Eternal Archives: Creates truly permanent digital archives for national libraries, museums, historical societies, and government records, ensuring that future generations can access and learn from humanity’s past.

* Safeguarding Endangered Cultures: Preserves digital records of endangered languages, traditional knowledge, and cultural practices for posterity.

* Personal Digital Legacy: Could offer a solution for individuals to create truly long-lasting digital legacies, storing family histories, personal documents, and memories for their descendants.

* Architectural and Urban Planning Archives: Preserving detailed digital models and data for historical buildings and urban environments for future restoration or study.

6.5. Defense, National Security, and Immutable Records

In military and intelligence applications, the need for secure, immutable, and long-lasting storage of classified information, strategic intelligence, and critical operational data is paramount. This data often needs to be stored in environments where power might be intermittent or unavailable, or where resilience against physical threats is critical.

Impact:

* Secure Cold Storage: Provides an off-grid, physically secure medium for classified intelligence, strategic plans, and operational records that must survive for decades or centuries without power.

* EMP Resistance: Ceramic media would be largely immune to electromagnetic pulse (EMP) attacks, which could render most electronic and magnetic storage systems useless.

* Disaster Recovery: Critical for disaster recovery and continuity of operations, ensuring essential data survives catastrophic events.

* Verifiable Chain of Custody: The immutability makes it ideal for forensic evidence, intelligence logs, and critical audit trails where data tampering is absolutely unacceptable.

Ceramic-based data storage, with its inherent robustness and longevity, therefore stands as a foundational technology not just for the burgeoning data center industry but also for safeguarding human knowledge, advancing scientific frontiers, ensuring national security, and enabling humanity’s long-term ventures beyond Earth. Its diverse applications underscore its potential to be a truly transformative force in the coming decades.

Many thanks to our sponsor Esdebe who helped us prepare this research report.

7. Future Outlook and Conclusion

Ceramic-based data storage represents a profound technological advancement in the perennial quest for durable, high-density, and energy-efficient solutions to manage humanity’s ever-expanding digital footprint. Innovations championed by pioneering companies such as Cerabyte unequivocally demonstrate the substantial potential of this technology to address the escalating demands of data preservation across an eclectic range of sectors, from hyperscale cloud providers to deep space exploration missions.

The unique amalgamation of properties inherent in ceramic materials—extreme hardness, chemical inertness, thermal stability, and resistance to environmental degradation—coupled with the robust, scalable platform of glass substrates, positions ceramic storage as a paradigm shift. The precision afforded by femtosecond laser-material interaction, enabling the inscription of data as immutable physical changes at the nanoscale, provides a compelling alternative to traditional media that are prone to decay and obsolescence. Furthermore, the strategic design to leverage existing high-volume glass manufacturing infrastructure offers a pragmatic pathway to commercial scalability, an advantage not always shared by other nascent ultra-long-term archival technologies.

While significant challenges remain, particularly in scaling manufacturing processes to exabyte-level capacities and further optimizing cost-effectiveness for widespread market adoption, these hurdles are not insurmountable. They present fertile ground for continued research and development, inviting interdisciplinary collaboration across material science, laser physics, optical engineering, and data management. Strategic partnerships with key industry players and sustained investment, as evidenced by support from entities like Western Digital and In-Q-Tel, are vital accelerators for bridging the gap between cutting-edge innovation and commercial reality.

Cerabyte’s ambitious roadmap, targeting an astounding 100 petabytes per rack by 2030 and envisioning future densities reaching 100,000 petabytes per rack, underscores the transformative potential of this technology [5, 7, 8, 9]. Such capacities would redefine the economics and logistics of cold and deep archival storage, drastically reducing energy consumption, physical footprint, and the total cost of ownership over its projected multi-millennia lifespan. This makes ceramic memory a cornerstone technology poised to enable the ‘yottabyte era’ of data, where currently unfathomable volumes of information can be stored and accessed sustainably.

In conclusion, ceramic-based data storage is not merely an incremental improvement; it is a fundamental re-imagining of how digital information can be preserved. As global data generation continues its exponential trajectory, technologies that offer genuine longevity, unparalleled resilience, and efficient operation will become indispensable. Ceramic-based storage, with its promise of enduring digital integrity for centuries, is poised to become a foundational element of future archival systems, ensuring the integrity, accessibility, and sustainability of humanity’s digital legacy for generations to come.

Many thanks to our sponsor Esdebe who helped us prepare this research report.

References

- Cerabyte. (2025). How it works. Retrieved from cerabyte.com

- Cerabyte. (2025). Store all data virtually forever. Retrieved from cerabyte.com

- Snia Developer. (2025). Ceramic Nano Memory – Data Storage for the Yottabyte Era. Retrieved from sniadeveloper.org

- DatacenterDynamics. (2025). Ceramic long-term storage company Cerabyte secures investment from Western Digital. Retrieved from datacenterdynamics.com

- Tom’s Hardware. (2025). Laser-engraved ceramic storage device that stores data for 5,000 years targets astounding 100 petabytes per rack by 2030. Retrieved from tomshardware.com

- TechSpot. (2025). Ceramic Nano Memory comes to the US, promising a data storage revolution. Retrieved from techspot.com

- Guru3D. (2025). Cerabyte Ceramic Nano Memory Plans 100PB Storage by 2030. Retrieved from guru3d.com

- What PSU. (2025). Cerabyte aims to achieve 100 PB Ceramic Nano Memory Storage by 2030. Retrieved from whatpsu.com

- TechRadar. (2025). Ceramic-based startup wants to put more than 100,000TB in a 42U rack by 2030. Retrieved from techradar.com

- Pipedot. (2025). Cerabyte Ceramic Storage Poised To Usher In ‘Yottabyte Era’. Retrieved from pipedot.org

- DatacenterDynamics. (2025). Ceramic long-term storage startup Cerabyte secures investment from In-Q-Tel. Retrieved from datacenterdynamics.com

- TechRadar. (2025). After Pure Storage, CIA-backed VC invests in ceramic-based startup that wants to build Exabyte-class storage. Retrieved from techradar.com

- TechSpot. (2025). The future of data storage might be ceramic glass that can last thousands of years. Retrieved from techspot.com

The exploration of ceramic-based data storage for cultural heritage preservation is compelling. Could this technology also revolutionize how museums and archives manage and provide access to digitized collections, moving beyond simple storage to create interactive and immersive experiences for users?

That’s a fantastic point! Absolutely, the potential for interactive experiences is huge. Imagine museums using this tech not just for archiving, but for creating dynamic, layered exhibits where users can delve deeper into artifacts and historical data. It opens doors to a whole new level of engagement and education.

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

Ceramic storage lasting 5,000 years? Finally, a digital equivalent of those ancient scrolls! But will future archaeologists be able to find the right drivers to read the data? Perhaps they’ll need to invent a ‘digital Rosetta Stone’ just to access our cat videos and tweets.

That’s a fun thought! The “digital Rosetta Stone” concept is certainly a challenge we’re considering. The longevity of the medium is only half the battle; ensuring accessibility through standardized formats and open-source retrieval methods is crucial for future-proofing the data. We’re exploring ways to embed this directly within the storage itself!

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

The report highlights ceramic data storage’s potential in space exploration due to its radiation hardness. Could this technology also provide robust storage solutions for terrestrial environments with high levels of electromagnetic interference, such as industrial facilities or research labs, expanding its application beyond archival purposes?

That’s an excellent question! Absolutely, the radiation hardness that benefits space exploration also makes it suitable for electromagnetically noisy environments. Industrial facilities and research labs with sensitive equipment could greatly benefit from robust data storage unaffected by interference, leading to reliable data capture and process control. Perhaps even medical imaging? What are your thoughts?

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

5,000 years is impressive! But what about those alien artifacts we keep hearing about? Seems like this ceramic data storage would be perfect for decoding their secrets without accidentally vaporizing them with our current tech. Just a thought!

That’s a fascinating thought! The non-destructive aspect is certainly a plus. Also, the stability to extreme environments would be a big advantage in storing/ analyzing findings made in space – thanks for sparking this discussion!

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

Given the system’s reliance on femtosecond lasers for writing, how might advancements in laser technology, specifically in areas like pulse shaping and multi-photon absorption, further optimize data density and writing speeds beyond current projections?

That’s a great question! Exploring pulse shaping to tailor energy deposition more precisely could significantly boost writing speeds and data density. Also, advancements in multi-photon absorption could allow us to manipulate the ceramic material at even smaller scales. This opens up some exciting possibilities for future development!

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

The emphasis on leveraging existing glass manufacturing processes is a key advantage. Exploring partnerships with established glass manufacturers could accelerate scalability and reduce initial capital expenditure, making this technology more accessible.

That’s a great point! Collaboration is key. Partnering with experienced glass manufacturers offers huge advantages in scaling production. Their expertise can help us optimize the process and reduce costs, making this groundbreaking storage solution available to a wider audience sooner.

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

Given the emphasis on extreme longevity, what methods are being explored to validate the 5,000+ year lifespan claims, especially considering accelerated aging techniques may not fully replicate real-world degradation factors over such extended timescales?

That’s a vital question! While accelerated aging provides valuable insights, we are developing predictive models combining material science and environmental simulations. Long-term monitoring of real-world samples under diverse conditions is also planned to refine our lifespan estimates. It’s crucial to correlate accelerated testing to real time observation. What parameters do you think are most important to monitor?

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

The discussion of leveraging existing glass manufacturing processes is insightful. I wonder how the integration of ceramic nanolayer deposition into established float glass or similar production lines might influence the overall cost and scalability, especially considering the need for high precision and defect control.

That’s an insightful question regarding nanolayer deposition! The goal is to adapt existing float glass lines while incorporating stringent quality checks. Inline metrology and automated optical inspection will play crucial roles. Reducing defect density early in the process is critical for maintaining cost-effectiveness and high throughput as we scale production. Thanks for bringing this up!

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

5,000 years? That’s cute. I’m already brainstorming how we can use this for interstellar messages in a bottle. Imagine aliens finding our ceramic cat memes millennia from now. Talk about a cultural exchange!

Haha, love the interstellar message in a bottle idea! It really highlights the longevity potential. Thinking about cultural exchange, what kind of data or information do you think would be most valuable/interesting to send to another civilization? Beyond cat memes, of course!

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

Ceramic storage in deep space, you say? Finally, a way to send all those unread emails on a one-way trip to the Andromeda galaxy. Perhaps they’ll appreciate the spam more than we do!

Haha! That’s a creative solution to inbox overload! The extreme durability is definitely overkill for spam disposal. But thinking about long-distance communication, what kind of interstellar ‘message in a bottle’ do you think would best represent humanity? Or maybe a playlist?

Editor: StorageTech.News

Thank you to our Sponsor Esdebe

The discussion of future applications is fascinating. The potential for cultural heritage preservation, ensuring access to digitized collections for future generations, highlights the profound societal impact of this technology. What strategies will ensure these archives remain accessible despite evolving technology?